THE CAMM® TECHNOLOGY

DESIGNED TO PERFORM.

HEALTHY FOR PEOPLE AND THE PLANET

CAMM® is a breakthrough pellet material that performs like plastic - without its negative side effects

Engineered from biodegradable, non-toxic ingredients, CAMM® serves its purpose - then returns to nature without leaving microplastics, toxins, or chemical residues behind.

Like an apple on the compost, or a leaf in water.

Just as important: CAMM® meets technical and commercial standards that real-world adoption demands.

Because real change happens when a solution succeeds in the mainstream.

DISSOLVES WITHOUT MICROPLASTICS

CAMM® dissolves when exposed to water or compost conditions - breaking down in a way that mirrors nature’s own decomposition process.

Depending on the formulation and application, CAMM® dissolves in minutes or months.

But the result is always the same:

No trace. No harm. No clean-up needed.

And no microplastics.

Because CAMM® is truly water-soluble, its carbon chains break apart on contact - unlike conventional plastics or even many bioplastics.

What’s left is consumed by natural microorganisms in soil or water.

This is science aligned with nature’s rhythm - a material intelligently designed with its own built-in exit.

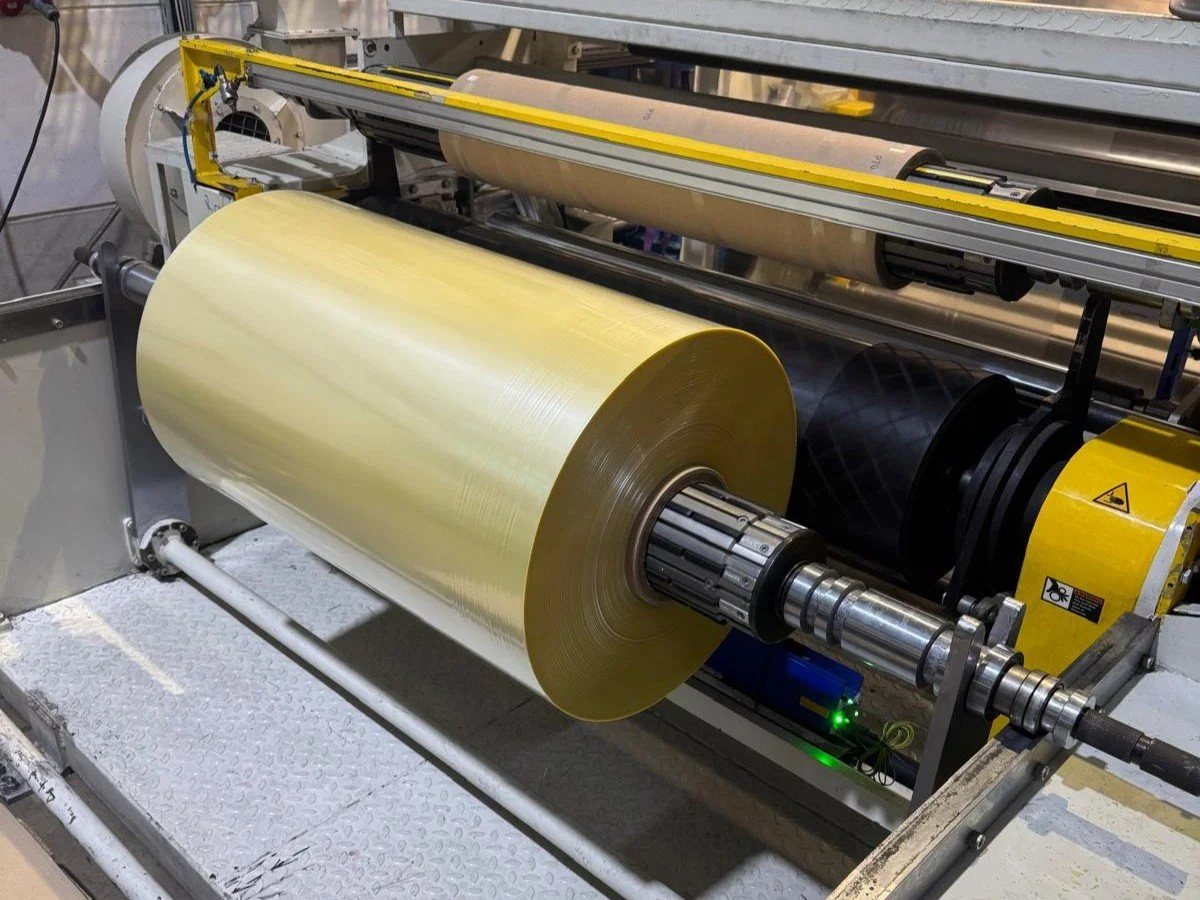

INDUSTRIAL MACHINE APPROVED

Making new materials is easy.

Getting them to run on real-world machines? That’s the hard part.

At CAMM®, we’ve done what most young materials companies can’t:

We’ve taken a breakthrough idea — and made it work at industrial scale.

Today, CAMM is already running on machines worldwide, powering applications like:

Fiber-based flexible packaging

Film packaging

Rigid packaging solutions

Our solutions have been validated by leading machine manufacturers —

and are ready to replace significant volumes of plastic across industries.

CAMM® pellets — the base material — are produced in our Spanish facility,

with an annual capacity of 7,000 tons and growing.

Conversion takes place through a global network of partners in Europe with US coming next, bringing CAMM into the mainstream — where change actually happens.

ENABLES HIGH-QUALITY RECYCLING

CAMM® enables clean, high-yield recycling — especially when used as coating or laminate on paper.

In the paper pulping process, CAMM dissolves on contact and biodegrades completely.

This allows over 99% of the paper fibers to be recovered — without clogging systems, leaving microplastics, or compromising material quality.

By separating cleanly from the paper,

CAMM simplifies recycling and supports full fiber recovery, deinking, and decolorization.

Designed to meet PPWR requirements,

CAMM fits into today’s recycling systems.

TESTED AND CERTIFIED

CAMM® has been rigorously tested and independently certified for performance, safety, and environmental compatibility.

COMPOSTABLE

EN 13432: OK Compost Industrial certification.

EN 13432 (adapted for home compostability) and ISO 20200: OK Compost Home certification.

BIODEGRADABLE

ISO 14851: Freshwater biodegradability study by OWS.

Marine biodegradability: Biodegrades within 266 days, verified in a study by OWS (ASTM D6691).

NON-TOXIC

ISO 7346 / OECD 236: No harm to fish in aquatic environments, verified by University of Valencia & Hydrotox GmbH.

UNE 6341 / OECD 202: Non-toxic to sensitive aquatic species, verified by University of Valencia & Hydrotox GmbH

OECD 201: Non-toxic to water algae growth, verified by Hydrotox GmbH.

MICROPLASTIC-FREE

Verified by Stuttgart University and Horiba Laboratories (deep dive study & Raman Spectroscopy).

RECYCLABLE (CAMM® + PAPER)

EN 13430: European recyclability standards compliance.

(Recycling analyses were performed according to harmonized CEPI method from October 2022.)

FSC® CHAIN OF CUSTODY CERTIFIED

Products with CAMM® containing paper come from responsibly managed forests and are FSC®-certified (FSC® C218407).