Replace Plastic.

Restore the Planet.

CAMM® delivers the strength and versatility of plastic packaging—without the environmental cost.

Engineered for seamless integration with existing industrial machinery, CAMM® empowers packaging companies and brand-owners to transition to authentic sustainable packaging—without compromising performance or commercial viability.

When paired with paper, CAMM® sets a new standard for responsible, future-ready packaging.

From pellet to packaging - through partnership

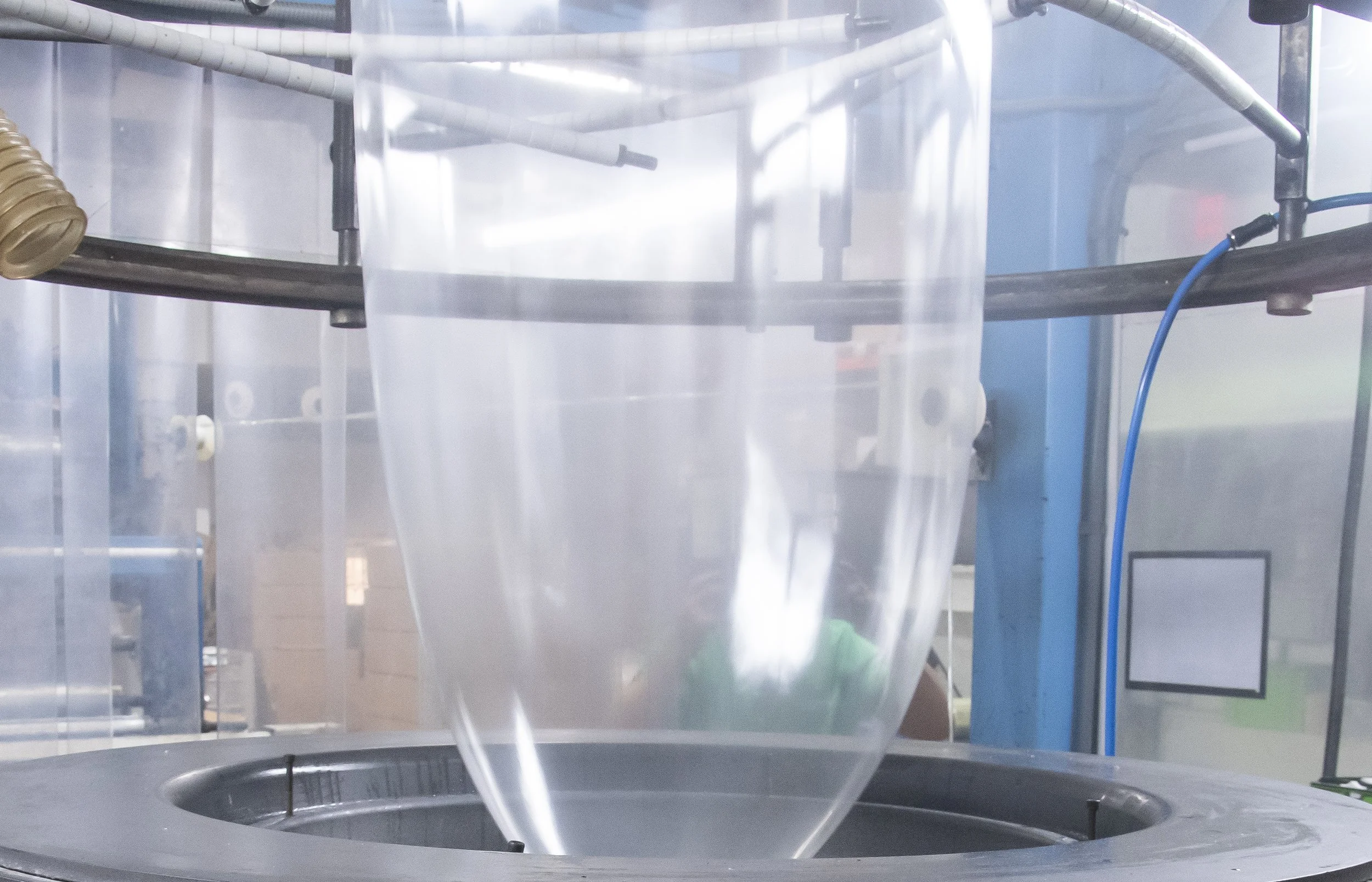

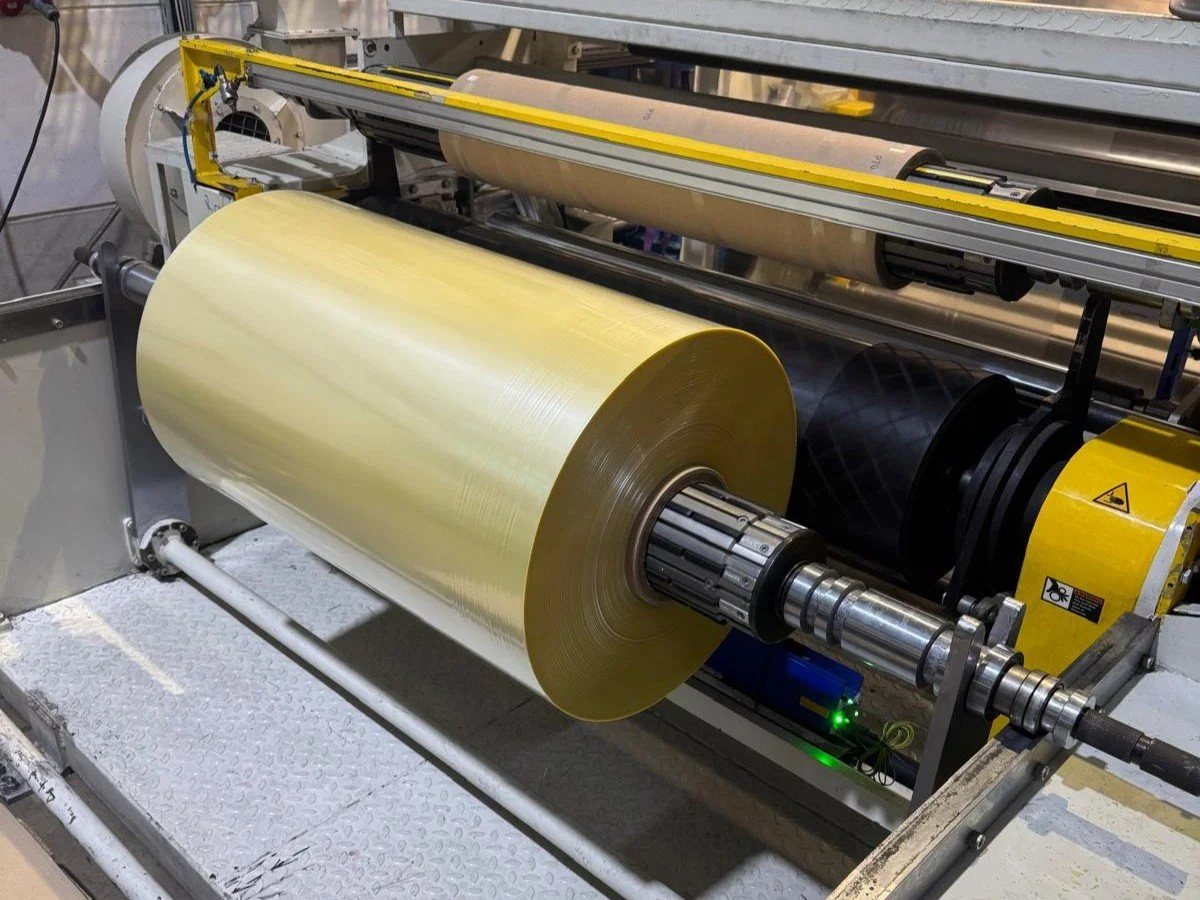

Camm Solutions offers CAMM® pellets and coatings that are produced in our European facility in Valencia, Spain. For optimal collaboration with our packaging partners and brand owners we have onsite piloting lines and semi-industrial conversion for film and injection molding.

A state-of-the-art laboratory allows us to conduct standard functional, migration and barrier tests.

Reducing global plastic waste is our mission. And this means that packaging with CAMM® must ultimately reach end-consumers. This is why we have actively built an ecosystem for converting partners and packaging producers to make packaging available with CAMM®.

We train and certify our partners to ensure that CAMM® works on standard machines at standard speeds and temperatures, making the most out of the material.

Sustainable Packaging made with CAMM®

Where can we buy products made with CAMM®? What can you make out of CAMM®? These are frequently asked questions. The truth is: If fully scaled and all R&D potential were built out, we could replace 50% of plastic packaging worldwide. The breadth is enormous.

Our focus lies on those applications that solve key plastic problems.

If you are interested, please get in touch with us and we will redirect you to our dedicated packaging partners who produce and sell teh end-applications with CAMM®.

Polybags

Air Pillows made with CAMM®

Film Applications: Laundry bags, Dosing Bags, Stretch Film